The basic role of a lubricator is to drive oil or grease into

the lubrication point, ensuring the smooth operation and prolonged life of

machinery, minimal wear and tear, and avoid downtime. Inexpensive and simple

to fit, Single-point lubricator take seconds to install while bringing a wide

array of benefits:

- Maximize efficiency

- Save hundreds of maintenance hours

- Increase up-time

- Boost reliability and safety

- Eliminate human error

- Move away from scheduled maintenance

- Provide continuously, uninterrupted lubrication to the individual, expensive components

Types of Automatic Single Point Lubricators

- Gas-powered Lubricator

- Electro-chemical Lubricator

- Electro-mechanical Lubricator

*Gas-powered Lubricator :

The gas-powered units are actuated by mixing

an electrolyte and zinc pellet to form a gas. The gas expands against a plunger

that pushes the grease out of the unit at 45 PSI. They have a 3-6-9-12 month

dispensing range that requires a different concentration of zinc. However, they

are temperature-dependent.

That is, when

it is 0° they will push harder for less grease; whereas, when it is 90° they

will work less to lube the bearing. Some of the canisters are made of metal so

you will not know if the unit is operating properly or injecting the grease.

These cost the least out of the 3 and are a throw-away.

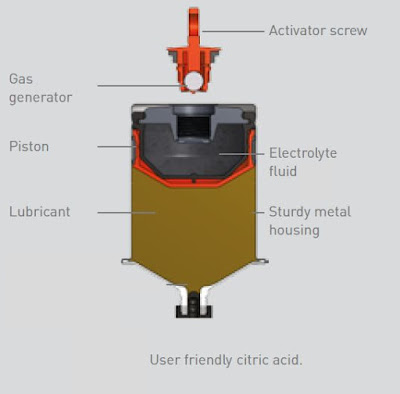

*Electro-chemical Lubricator

Electrochemical

units use a battery, microprocessor and an electrolyte to create a gas that

pushes the grease. The processor tells the battery to excite the electrolyte to

create a gas. The processor compensates for low temperature.

When it is

10° the processor senses it and adjusts the unit accordingly. The unit

dispenses the same amount of lubrication no matter what the outside temperature

is. Some units have dip switches or jumpers that can be set for each of the

different month settings. These units can be paused or turned off if the

equipment is going to be out serviced for a while.

*Electro-mechanical Lubricator

All

electromechanical lubricators have a battery, pressure source, programmable

controller (LED). And grease pack. The

LED controls a motor that pushes the grease. The type of motor dictates the

amount of pressure the unit is capable of. This is important depending on how

far the bearing tap is from the unit.

They have

replaceable batteries and grease packs so purchasing the complete unit are not

necessary, making it economical after the initial purchase is made. The most important feature is the feedback if the bearing does not accept the

lubrication which separates it from the other two types of lubricators.

If the

bearing or lube line is clogged and the unit can not push the grease, a fault

occurs. There will be a flashing indication on the LED. This is very important

for critical bearing. If and when this occurs some units have a memory that can

be checked to see when the last lube event took place.

The units

that can produce a pressure of 400 PSI plus can do multiple bearings using a

divider valve. They can do 1 to 8 bearings because they lube only one bearing

at a time. Keeping in mind the shorter the lube lines the better.

![What Is [ Lubrication ] ?](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgET6e2kj8GQcaAjy9r__Vrl2Bj4gc1j0dF7ASnrKCW6NA4d02Nk-Cljmkepa9XSydD_SiKP0p-qMkMAIZGAC5FFZIoOxOLa_Yx9WDCc1G63Qk6Yt5CU6YU8lLzKZ_7fHhfeuSECXy7kdq9/w680/What+is+Lubrications.jpg)

0 Comments